What Is a Production Printer?

Digital production printers have brought a transformative era in printing technology. These high-speed, high-volume printers, also known as commercial-grade digital presses, are true printing powerhouses – combining unprecedented speed and volume with unparalleled precision and efficiency.

You’re probably reading this to learn the true cost of a production printer, and the logistics of bringing production print in-house. These are questions we encounter often. We wrote this comprehensive article to give you an authoritative answer on the cost of the device and attendant service costs, as well as provide some additional context that will guide your decision making. (As always, our expert, brand-neutral production print team is available to answer your specific questions.)

What Can a Production Printer Do?

Depending on the type, tier, model and selected accessories, a production printer can produce a wide range of media for internal and external use, including:

- Annual Reports

- Bulk mail

- Calendars

- Catalogs

- Custom product boxes

- Handbooks and Manuals

- Product Packaging

- Posters

- Magazines

- Menus

- … and much more.

Production printers can:

- Output a wide range of high-quality print materials, including vivid color prints and sharp monochromes. They can produce mass quantities of printed materials, from sleek marketing pamphlets to detailed architectural blueprints.

- Print on a variety of media, including specialty finishes and thick card stock.

- With the capability to achieve up to 2400×4800 dpi resolution, they ensure every output, from intricate reports to fine art, is marked by crisp clarity, vibrant colors, and detailed contrasts.

- The inclusion of 5-color and 6-color options allows for designs that leverage neon and clear-gloss and invisible inks. Neon, metallic and clear coats can be used to elevate the quality and uniqueness of print projects, catering to stringent branding. Invisible inks, are often used for better security, to print bar codes and to avoid product counterfeiting.

One of the most compelling features of production printers is their remarkable flexibility in handling different media types and customizing prints. This adaptability makes them invaluable for creating everything from custom marketing banners to personalized reports, employing databases for tailored content that engages targeted audiences more effectively.

In essence, production printers enable businesses to efficiently produce a wide range of high-quality, professional-grade printed materials, supporting a variety of operational, promotional, and informational purposes.

Production Printer Types

The world of production printing is rich with variety, each type designed to meet specific printing demands:

Wide-Format Printers

Ideal for producing large visuals like banners and murals, accommodating materials up to 100 inches wide.

Cut-Sheet Printers

Suited for shorter print runs with their rapid output, boasting capabilities for high-resolution prints and significant monthly volumes.

Continuous-Feed Printers

Aimed at high-volume tasks, these printers are perfect for extensive projects such as book printing and large-scale mail campaigns.

How Much Does a Production Printer Cost?

Production printer leases are generally structured in two parts: the price of the equipment itself, and the price for the service. The costs shared in this article are based on the assumption that the lease includes both components. Considering the complexity and high production demand on this equipment, we consider a service component essential to avoid costly downtime and expensive repairs due to neglected maintenance.

Depending on the size and complexity of a production printer, prices can range from $20,000 to $200,000+. (There are some rare cases of high-end, sophisticated production printers costing over $500,000, but it’s unlikely this will be the case for most readers.)

Production Printer Tiers

To explain this wide range, we have segmented production printers into 3 tiers:

Tier I Production Printers

Price Range: $20,000-$70,000

Finishing Options: Typically limited to standard paper and basic finishing needs

Volume Capacity:

- Color prints: 20,000-100,000 prints per month

- Black & White: 80,000-200,000 prints per month

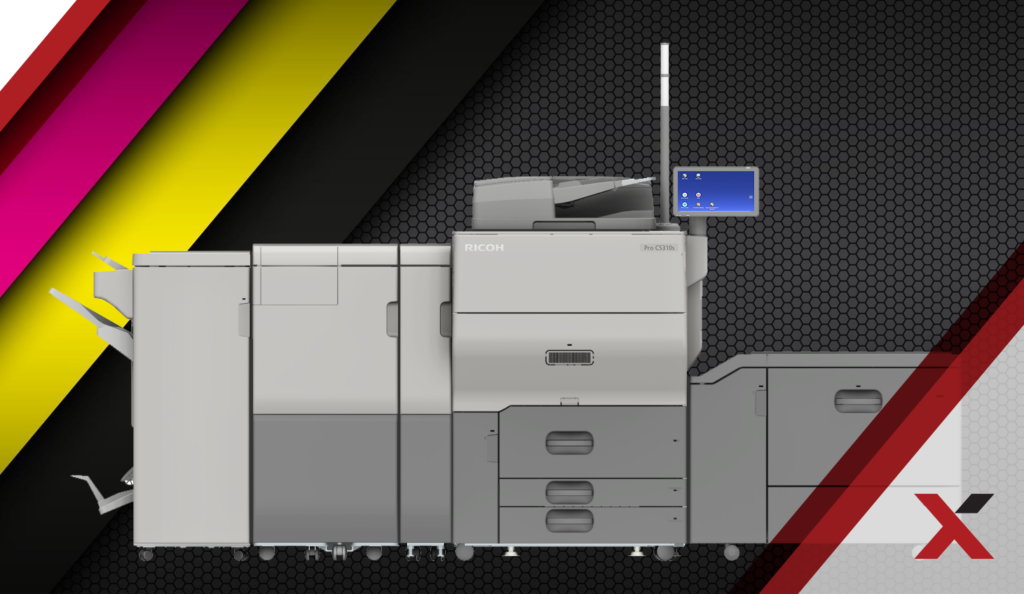

Pictured: Ricoh Pro C5300s

- Production Speed: 65 ppm color/65 ppm black*

- Maximum Duty Cycle: 450,000 impressions

- Recommended Monthly Volume: 150,000 impressions

- Max. Resolution: 2400 x 4800 dpi

- Device runs at 65 ppm when using paper weight ranges of 52 to 256 gsm.*

Device runs at 50 ppm when using paper weight ranges of 256.1 to 360 gsm.

Use Cases:

Tier I production printers are the most basic of all high-grade commercial print machines. These are well-suited for organizations with periods of high volume demand, but no rigorous demand for high quality beyond that of a laser printer. Examples of this use case are businesses or nonprofits with a quarterly newsletter. The high volume required would overwhelm a standard office printer.

Tier II Production Printers

Price Range: $70,000-$200,000

Finishing Options: Mid-level

Volume Demands:

Color: 80,000-500,00 prints per month

Black & White: 100,000-1,000,000 prints per month

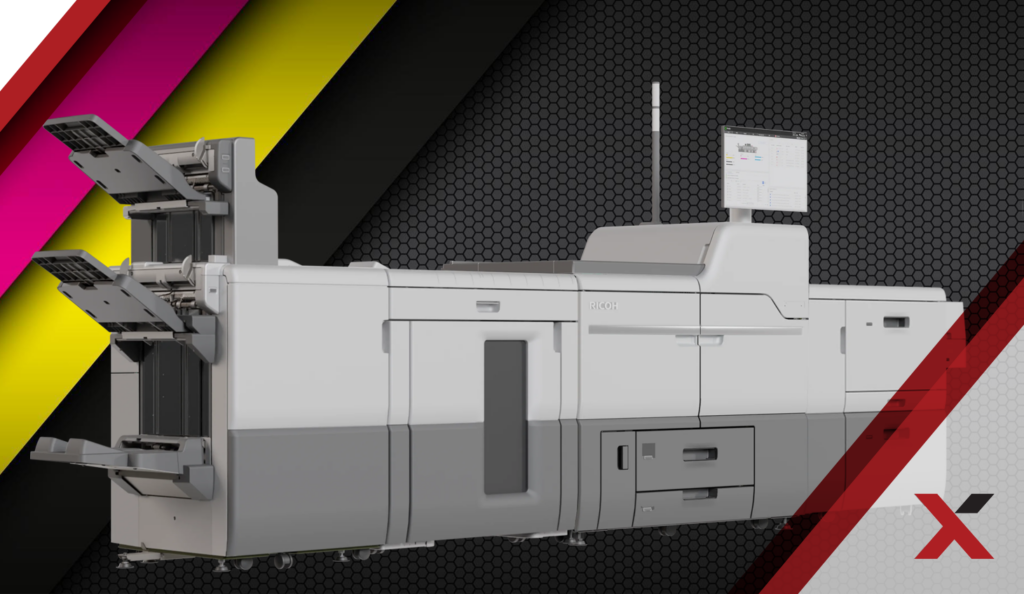

Pictured: Ricoh Pro C7500

- Production Speed: 85 ppm color/85 ppm black

- Maximum Duty Cycle: 1,500,000 impressions

- Recommended Monthly Volume: 240,000 impressions

- Max. Resolution: 2400 x 4800 dpi

Use Cases:

Tier II machines are ideal for organizations with consistent periods of print volume, and a need for adequate quality – where vibrancy of color is important, but exact color match is not a stringent requirement. (These printers are not the ideal fit for print shops whose clients expect very high quality.) Some use cases are nonprofits, large churches, and school systems – organizations that consistently produce mailers, programs, or bulletins.

Tier III Production Print Machines

Price Range: $200,000 & up

Finishing Options: Mid-level to full finishing options included

Volume Demands:

- Color: 80,000-500,000 pages per month.

- Black & White: 300,000-10,000,000 pages per month.

Pictured: Ricoh Pro C9500

- Production Speed: 115 ppm color/115 ppm black

- Maximum Duty Cycle: 1,750,000 impressions

- Recommended Monthly Volume: 1,000,000 impressions

- Max. Resolution: 2400 x 4800 dpi

Use Cases:

Tier III production printers output the highest speed and image quality. These powerful machines are perfect for large print shops or other operations that consistently have a need for in-house, high-volume quality printing.

Examples of such a use case are theaters or concert halls that consistently produce custom programs. These organizations can realize significant cost savings bringing their production print in-house by purchasing or leasing a Tier III production printer.

Organizations with intermittent high-volume printing needs might find such a machine to be overkill – and might find this costly machine under-utilized in the future.

Production Printer Service Costs

Typically, service costs evidence the widest range. (This range is justified, as each organization will have different service needs – so don’t be too quick to jump to the lowest service option.)

Black and White Service Supplies and Maintenance

Between .0025 – .004 per impression depending on volume and type of unit.

Color Service, Supplies and Maintenance

Between .037 – .049 per impression depending on volume and type of unit

The challenge for the equipment buyer is that what might look like a great bargain is really just the vendor leaving something out. When comparing service costs, make sure the proposed service includes auto-toner renewal and preventative maintenance. Some proposals include per-visit fees, and these can become a larger expense.

Often, what seems to be a great deal (on service or equipment) is just a company leaving something out. Sometimes, the machines being quoted aren’t even in the same classification, so it’s very important to look at your contract and negotiate, if necessary.

Make sure the vendor servicing your production printer has a committed, dedicated production service team, to provide you the highest level of service commitment and response time.

Some dealers boast of a quick response time, but when the service technician arrives, they’re missing the needed parts to properly service the unit, resulting in multiple visits.

Companies that charge a bit more for their services tend to pay their staff better and attract the best and brightest technicians. This benefits the customer, as it results in reduced downtime and more reliable service.

Is a Production Printer the Right Choice for My Organization?

Determining the need for a production printer begins with evaluating your organization’s print volume, quality requirements, and the complexity of your print jobs. Production printers, designed for high-volume, high-quality printing, are ideal for businesses that regularly produce materials such as manuals, catalogs, flyers, and posters. These robust machines offer superior speed, quality, and efficiency for entities like publishing houses, marketing departments, architectural firms, and construction companies.

Is a Production Printer Right for Your Business?

Request an assessment today to explore if a production printer solution is the right solution for your company’s needs.

Reasons to Bring Production Print In-House

- High-Volume Printing Needs: If your current print queues are bogging down workflows or if you’re outsourcing large print jobs to maintain productivity, a production printer can provide the capacity and speed you need.

- Quality and Customization: The superior output quality of a production printer can significantly enhance the materials that represent your brand, such as client proposals, marketing collateral, and product packaging, manuals, business cards, etc.

- Cost-Effectiveness: Analyzing your current print costs may reveal that the per-page cost of outsourcing or using smaller office printers is costing you dearly. A production printer might prove a money saver when considering bulk printing.

- Agility & Streamlined Workflow: Lead times, shipping, delivery or pickup arrangements, delays in proofing cycles can bog down your operation. Not only that, but they can lead to compromises in quality when working with tight deadlines. With an in-house printing operation, your team can iterate in an agile manner, allowing for shorter proofing cycles. You can also quickly output short runs and add personalization.

- Security & Confidentiality: Whether you’re a Healthcare organization concerned about HIPAA violations or a law firm worried about client confidentiality, high-volume printing of sensitive materials that include client or patient private information is best kept in-house, eliminating many potential vulnerabilities and risk factors of outsourced printing.

RELATED: The benefits of bringing production print in-house

What Should I Know Before Purchasing a Production Printer?

Before investing in a production printer, understanding the landscape of features, capabilities, and configurations is crucial. Here’s what to consider:

- Print Volume and Speed: Assess the print speed and volume capacities of different models to ensure they align with your needs.

- Media Compatibility: Production printers can handle a wide range of media types and sizes, from cardstock to linen. Ensure the printer supports the materials you commonly use.

- Image Quality: Look for printers that offer high resolution and color fidelity to ensure your printed materials meet your standards.

- Finishing Options: Consider whether you need additional features like binding, folding, or cutting, as these can influence the overall cost and utility of the printer.

- Software and Integration: Evaluate the software solutions provided for print management and workflow integration to enhance efficiency.

- Service and Support: Understand the warranty, maintenance services, and support offered by the manufacturer or vendor to mitigate downtime.

Is a Production Printer Right for Your Business?

Request an assessment today to explore if a production printer solution is the right solution for your company’s needs.

Measuring the ROI of This Purchasing Decision

Calculating the return on investment (ROI) for a production printer involves comparing the total cost of ownership (TCO) against the cost savings and value it brings to your organization. Key factors in this calculation include:

- Reduced Outsourcing Costs: Quantify what you currently spend on outsourcing print jobs that could be brought in-house with a production printer.

- Operational Efficiencies: Consider the value of time saved by having on-demand printing capabilities and faster turnaround times for print jobs.

- Print Cost Per Page: Calculate the anticipated cost per page based on the printer’s consumables and maintenance requirements, and compare it to your current costs

- Longevity and Scalability: High-quality production printers can serve your business for many years and adapt to growing demands, contributing to long-term savings.

Pros and Cons of Bringing Production In-House

Pros

- Control and Flexibility: Having a production printer on-site provides unparalleled control over your print jobs, including the timing, quantity, and quality.

- Cost Savings: Over time, in-house production can offer significant cost savings, particularly for businesses with heavy print volumes.

- Customization and Quality: In-house production enables higher quality outputs with extensive customization options, enhancing your materials’ effectiveness and brand representation.

Cons:

- Upfront Investment: The initial cost of purchasing a production printer can be substantial, requiring careful financial planning. (That said, if you compare your current cost for outsourced print jobs to the monthly cost of a lease, in-house production print could actually save you money.)

- Space and Infrastructure: Production printers vary in size – from a footprint of 3’ x 4’ to the size of a tractor-trailer. The larger, Tier III production printers require a large facility, and this needs to be accounted for. Depending on your printing needs, bringing production print in-house may include finding a new home for your print operation. (Reach out to our production print team for an accurate assessment of your production-print needs.)

- Training and Maintenance: Bringing production print in-house will include training staff. Fortunately, the newer production printers are quite easy to operate. Ongoing maintenance is vital. A great solution is to engage with an MPS (managed print services) partner such as Flex Technology Group.

Assessing Your Production Print Needs

Investing in a production printer is a significant decision that can transform your organization’s printing capabilities, offering cost savings, enhanced quality, and greater control over your print operations.

Before making this investment, it’s essential that you take time to properly assess your print needs, understand the full scope of ownership costs, and calculate the potential ROI.

Reach out to our production team today to request an assessment. Let our production print experts evaluate your print volume, rate of utilization, cost-per-page, required types of printed materials, formats, color options, and other factors – empowering you to make informed decisions that lead to the most positive outcome for your organization.

Is a Production Printer Right for Your Business?

Request an assessment today to explore if a production printer solution is the right solution for your company’s needs.